Equipment for repair of stop valves EFCO

Production GERMANY 1991-1992-1993 years of releaseMini-factory EFCO

In fact, this equipment is a mini-plant for complete repairing of valve slides with diameters from 20 mm up to 800 mm for oil and gas, oil-chemical and chemical industries. It includes:

- Welding machines

- Portable grinding-lapping machines

- Abrading-lapping machines

- Testing stands

- Car-type boring lathe machines

... enabling to swiftly deal with machine breakdown on the pipelines without having to remove the valve.

Specification for a mini factory of machines EFCO

Equipment and adaptations for processing, repair and testing of stop valves, flanges and pipelines of all kinds.The equipment is 97% electrically and mechanically complete and it has not been practically used. In general, it is a complex of machines for the full production cycle and it is not necessary to involve contractors and subcontractors or additional equipment. In this regard, it is being sold as ONE LOT in the total number of 52 pcs.

| № | Name | Number |

|---|---|---|

| № | Name | Number |

| 1 | Automatic machine for deposit welding of cylindrical surfaces ID Weld 25 | 1 |

| 2 | Static welding set CostoMatec 650 | 2 |

| 3 | Cover gasket cutter Rondella P 135 DI | 2 |

| 4 | Car-type boring machine EFCO-TD 1 | 1 |

| 5 | Polishing machine EFCO-FLM 1000 | 1 |

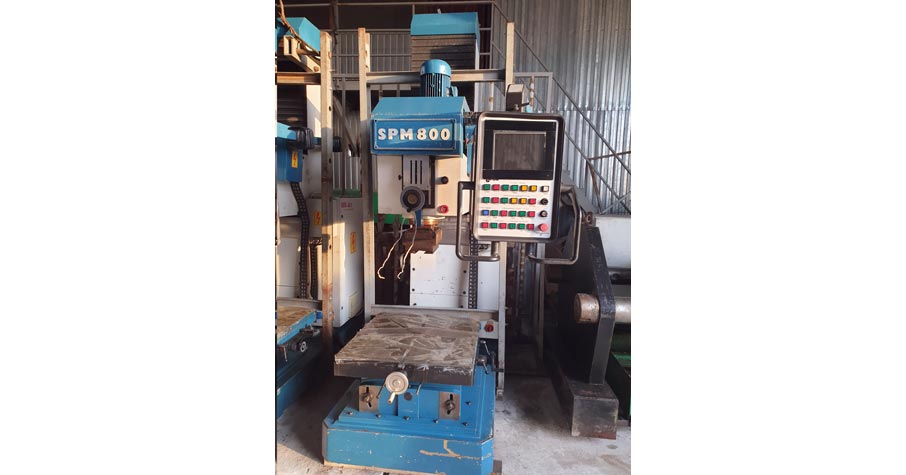

| 6 | Precision boring machine EFCO-SPM 800 | 1 |

| 7 | Precision boring machine EFCO-SPM 800 | 2 |

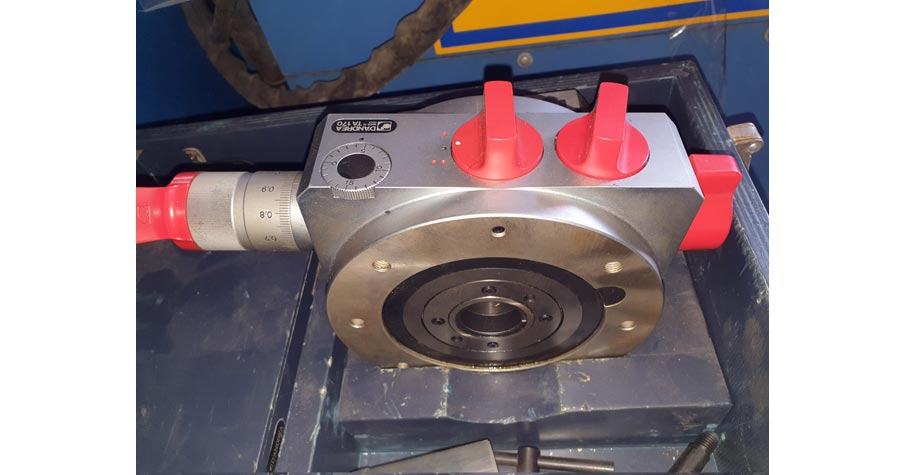

| 8 | Machine for grinding valve seats 30, 40, 75g. EFCO-VSК | 2 |

| 9 | Machine for grinding valve seats 60 g. EFCO-VSК | 2 |

| 10 | Machine for grinding valve seats 90g. DN 150 EFCO-VSК | 1 |

| 11 | Mechanized welding plant EnDotec 3000 | 3 |

| 12 | Grinding-and-lapping machine EFCO-SL 2 | 2 |

| 13 | Grinding-and-lapping machine EFCO-SL 2 | 1 |

| 14 | Grinding-and-lapping machine EFCO-SL 1 | 1 |

| 15 | Grinding-and-lapping machine EFCO-SL 15 | 3 |

| 16 | Grinding-and-lapping machine EFCO-VALVA 15 | 3 |

| 17 | Grinding-and-lapping machine EFCO-VALVA 2 | 2 |

| 18 | Grinding-and-lapping machine (with two tables) EFCO-SМ 750 | 3 |

| 19 | Grinding machine EFCO-SL 05 | 2 |

| 20 | Grinding machine EFCO-VALVA S15 | 1 |

| 21 | Grinding machine EFCO-VALVA SI | 5 |

| 22 | Grinding machine EFCO-VALVA SVI | 1 |

| 23 | Grinding machine EFCO-VSА 1 | 1 |

| 24 | Grinding machine EFCO-VSА 2 | 1 |

| 25 | Testing stand PS-30 | 1 |

| 26 | Testing stand PS-60 | 1 |

| 27 | Testing stand PS-100 | 1 |

| 28 | Remote panel PS-300 | 1 |

| 29 | Machine table PS-300 | 1 |

| 30 | Станок для заточки резцов | 1 |

| 31 | Компрессор поршневой 200 атмосфер | 1 |

Technical information

LLC "Modernizatsiya Mashinostroeniya"Hardware upgrade EFCO

We are also ready to modernize the equipment and to replace outdated CNC.

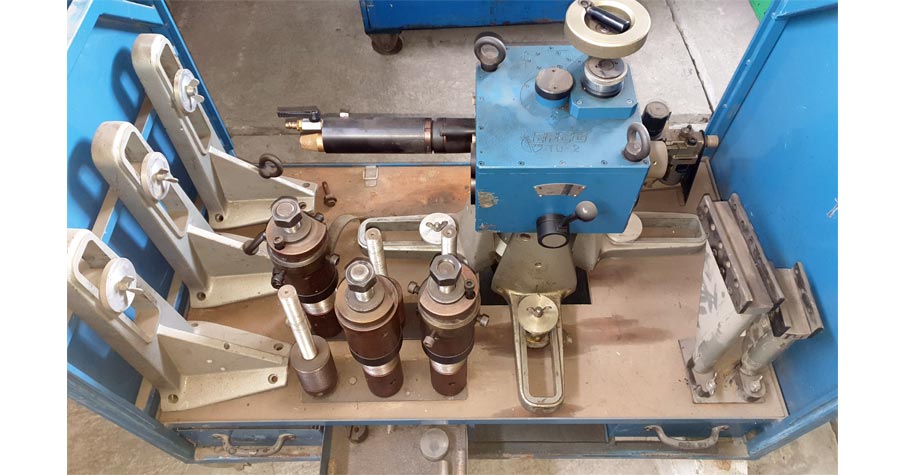

In addition to this equipment we can give you the machine-tool attachment as a BONUS and extra DISCOUNT. The attachments and accessories are packed in original factory packaging and have been never used. The completeness of the attachments is 75%. You should understand that the purchase price for these attachments in 2013 was about 700 thousand euros. Only a few stands and a hydraulic press were used. The rest equipment was put in dead storage. The factory grease and packaging can prove it. This equipment was purchased but not used as intended because of the collapse of the USSR and the rate of production that had sharply decreased.

Catalogs and passports for equipment EFCO

About us

LLC "Modernizatsiya Mashinostroeniya"

Andrey Tenkov

SUPPORTI am ready to offer this equipment being modernized or as it is in the present condition.

Vasily Galitskiy

DIRECTORMy company is the legal and beneficial owner. The equipment is on the balance of my company where I am the Director and Sole Founder.